Raws li qhov tseem ceeb ntawm lub tog raj kheej hydraulic, piston pas nrig yog siv nyob rau hauv tawv puag ncig thiab corrosive tej yam kev mob;Yog li ntawd, cov txheej txheem tiv thaiv zoo yog qhov tseem ceeb.Tam sim no, electroplating nyuaj chrome yog txoj kev dav.Vim nws cov kev ua tau zoo thiab tus nqi qis, electroplated nyuaj chrome yog ib txoj hauv kev rau kev kho piston pas nrig.

Cov txheej txheem ntawm piston pas nrig txheej

1) Toughness

Toughness yog ib qho tseem ceeb yam ntxwv ntawm piston pas nrig coatings.Cov coatings pom tsis zoo los yog tsis tawv txaus tsis tuaj yeem nqus tau ntau lub zog thaum lub pob zeb angular lossis tawv grit ntaus lub piston pas nrig, qhov kev puas tsuaj tshwm sim tau yooj yim, thiab lub tog raj kheej hydraulic yuav tsis ua haujlwm tam sim ntawd vim yog txheej txheej delamination lossis flaking.

Qhov kev ntsuam xyuas cuam tshuam yog ib qho kev sim dynamic uas ib qho kev xaiv feem ntau raug ntaus thiab tawg los ntawm lub viav vias pendulum.Qhov kev sim ntau tshaj plaws ntawm hom no yog Charpy V-notch test thiab Izod test uas tau piav qhia hauv ASTM E23.Lub hauv paus ntsiab lus sib txawv ntawm ob qhov kev xeem yog cov yam ntxwv ntawm cov qauv raug kho.

2) Corrosion kuj

Vim qhov chaw ua haujlwm tsis zoo, kev tiv thaiv corrosion tseem ceeb heev rau hydraulic lub tog raj kheej piston pas nrig txheej.Cov tshuaj tsuag ntsev yog ib qho kev sim ua qauv siv los kuaj xyuas qhov kev tiv thaiv corrosion ntawm hydraulic lub tog raj kheej piston pas nrig txheej;nws yog ib qho kev ntsuam xyuas kev tiv thaiv corrosion thiab cov tsos ntawm cov khoom siv corrosion raug soj ntsuam tom qab lub sijhawm.

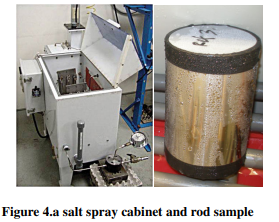

Cov cuab yeej siv rau kev sim raws li qhia hauv daim duab 4 muaj cov chav kuaj kaw, qhov twg cov kua ntsev, feem ntau yog cov tshuaj sodium chloride, yog txau los ntawm lub nozzle.Qhov no ua rau ib puag ncig corrosive nyob rau hauv lub chamber thiab yog li, qhov chaw nyob rau hauv nws raug tawm tsam nyob rau hauv no hnyav corroding cua.Cov kev ntsuam xyuas tau ua nrog kev daws ntawm NaCl yog hu ua NSS (neutral ntsev tsuag).Cov txiaj ntsig feem ntau raug ntsuas raws li cov sij hawm sim hauv NSS yam tsis muaj cov khoom siv corrosion.Lwm cov kev daws teeb meem yog ASS (acetic acid test) thiab CASS (acetic acid nrog tooj liab chloride test).Chamber kev tsim kho, cov txheej txheem kuaj, thiab cov kev ntsuas ntsuas yog cov qauv raws li lub teb chaws thiab thoob ntiaj teb cov qauv, xws li ASTM B117, DIN 50021, thiab ISO 9227. Tom qab lub sijhawm sim, cov qauv tuaj yeem ntsuas raws li qhov chaw rusted nto siv cov qauv siv raws li qhia. v tab 1.

3) Hnav tsis kam

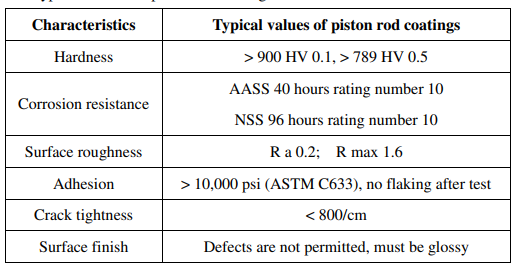

Raws li lub zog xa hluav taws xob, tus pas nrig piston yuav tsum txav mus los thiab rov qab tsis tu ncua, tib lub sijhawm hnav tshwm sim thaum lub sijhawm txheej txheej swb tawm tsam lub tog raj kheej sealing.Yog li kev hnav tsis kam kuj tseem yog qhov yuav tsum tau muaj rau piston pas nrig lub neej.Deg hardness yog qhov tseem ceeb parameter rau hnav tsis kam.Dhau li ntawm toughness, corrosion kuj thiab hnav tsis kam, raws li ntau yam kev lag luam cov qauv thiab cov neeg siv khoom, lwm yam txheej txheem ntawm piston pas nrig txheej yog teev nyob rau hauv lub rooj 2.

Yog xav paub ntxiv txog hydraulic lub tog raj kheej, hydraulic zog units, thov koj xav tiv tauj peb los ntawm:sales@fasthydraulic.com

Post lub sij hawm: Sep-23-2022