1. Dab tsi yog welded lub tog raj kheej?Lub thoob yog welded ncaj qha mus rau lub kaus mom kawg thiab cov chaw nres nkoj yog welded rau lub thoob.Lub caj pas pem hauv ntej yog feem ntau bolted los yog threaded rau hauv lub tog raj kheej chim, uas tso cai rau lub piston pas nrig sib dhos thiab cov pas nrig ntsaws ruaj ruaj yuav raug tshem tawm rau kev pab.Welded hydraulic thooj voos kheej kheej muaj ntau qhov zoo dua li khi pas nrig lub tog raj kheej.Txawm hais tias khi pas nrig lub tog raj kheej tuaj yeem pheej yig dua rau kev tsim khoom, lawv feem ntau suav tias yog "tawm ntawm lub txee" cov khoom thiab muaj kev txwv tsis pub muaj kev hloov kho.Lawv kuj tsis tshua muaj zog dua welded thooj voos kheej kheej.Welded lub cev thooj voos kheej kheej tuaj yeem tsim kho rau kev siv tshwj xeeb.Welded cylinders kuj muaj cov pob ntim zoo tshaj plaws, uas tuaj yeem pab ua kom lub neej ntev ntawm lub tog raj kheej thiab tuaj yeem muaj txiaj ntsig zoo thaum lub tog raj kheej yuav siv rau hauv qhov chaw uas muaj cov kab mob thiab huab cua.Aesthetically, welded lub cev thooj voos kheej kheej muaj cov khoom qis dua li khi condan thiab tuaj yeem txhim kho cov khoom siv ntawm cov khoom siv uas nws siv.Txij li thaum lawv nqaim dua li lawv txoj hlua khi sib npaug, welded hydraulic thooj voos kheej kheej ua haujlwm zoo hauv kev siv hauv qhov chaw yog qhov tseem ceeb.

2. Yuav ua li cas tswj qhov vuam zoo thaum lub sij hawm ntau lawm?

Cov khoom siv vuam;Npaj cov qauv vuam nruj me ntsis raws li cov txheej txheem ua ntej yuav tsum tau ua: Preheating, vuam, txuag hluav taws xob, thiab npaj cov qauv vuam.Thiab ua daim npav txheej txheem vuam los muab lub hauv paus rau kev siv cov vuam;Cov khoom siv vuam, vuam hlau thiab vuam roj yog cov khoom siv sib xws, kev ua haujlwm ruaj khov, roj purity siab, thiab qhov sib piv raug;Vuam tus neeg, yuav tsum muaj daim ntawv pov thawj welder;Vuam kuaj, xws li weld hlaws lub zog kuaj thiab kuaj ultrasonic los kuaj vuam zoo.

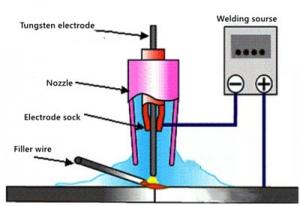

3. Gas shielded vuam yuav muab faib ua inert gas shielded welding (TIG welding), nquag roj shielded vuam (MAG vuam).Gas shielded vuam (TIG thiab MIG vuam).Pom tseeb, argon feem ntau siv vim nws tus nqi pheej yig dua, yog li inert gas shielded hlau arc vuam kuj hu ua argon arc vuam.tungsten inert gas welding yog txheej txheem vuam uas tungsten lossis tungsten alloy yog siv los ua cov khoom siv hluav taws xob, thiab cov arc generated ntawm cov electrode thiab cov khoom siv hauv paus yog siv los yaj cov khoom hauv paus thiab sau cov hlau nyob rau hauv kev tiv thaiv ntawm cov roj inert. .

TIG, tseem hu ua Gas Arc Vuam (GTAW), yog ib txoj hauv kev ua Arc ntawm Tungsten electrode thiab lub hauv paus hlau nyob rau hauv inert roj tiv thaiv kom lub hauv paus hlau thiab vuam hlau cov khoom yuav yaj thiab ces welded.Nws suav nrog DC TIG vuam thiab AC TIG vuam.

DC TIG vuam siv lub DC arc vuam fais fab qhov chaw ua lub vuam fais fab, nrog lub zog tsis zoo thiab cov khoom siv zoo.Nws yog tsuas yog siv rau vuam stainless hlau, titanium, tooj liab thiab tooj liab alloy.Lub vuam fais fab ntawm AC TIG vuam yog los ntawm AC arc, thiab cov anode thiab cathode ntawm cov khoom siv tau hloov pauv.EP polarity electrode overheating tuaj yeem tshem tawm cov khoom siv hauv qab oxide txheej, feem ntau yog siv rau txhuas, magnesium, thiab lwm yam hlau vuam.

Thaum TIG (GTAW) vuam ua haujlwm, tus welder tuaj yeem yog rab phom vuam hauv ib txhais tes thiab vuam hlau hauv tes, tsim nyog rau kev ua haujlwm me me thiab kev kho ntawm phau ntawv vuam.TIG tuaj yeem welded yuav luag tag nrho cov khoom siv hlau, nws muaj qhov zoo vuam zoo, tsawg slag thiab plua plav tuaj yeem siv dav hauv nyias thiab tuab steel phaj.

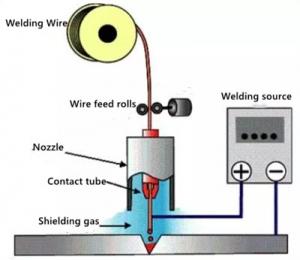

MAG (Metal Active Gas) Vuam siv CO₂ lossis sib tov ntawm argon thiab CO₂ lossis oxygen (ib qho roj nquag).Vuam ntawm CO₂ roj yog qee zaum hu ua CO₂ arc vuam.MIG thiab MAG vuam cov cuab yeej zoo ib yam uas lawv tuaj yeem pub tawm ntawm lub teeb los ntawm lub tshuab xaim tsis siv neeg thiab tsim nyog rau kev siv vuam tsis siv neeg, tsis hais txog kev siv vuam.Qhov sib txawv tseem ceeb ntawm lawv yog nyob rau hauv cov roj tiv thaiv, qhov qub yog feem ntau tiv thaiv los ntawm cov pa ntshiab argon, haum rau vuam tsis-ferrous hlau;MAG welding feem ntau yog siv CO₂ roj, lossis argon sib xyaw CO₂ nquag roj, uas yog Ar + 2% O₂ lossis Ar + 5% CO₂, tsim nyog rau vuam siab zog hlau thiab hlau alloy siab.Txhawm rau txhim kho cov txheej txheem kev ua haujlwm ntawm CO₂ vuam, CO₂ + Ar lossis CO₂ + Ar + O₂ sib xyaw roj lossis cov xaim flux-cored kuj tuaj yeem siv.MAG vuam yog tus yam ntxwv los ntawm nws cov vuam ceev ceev, siab arc pib efficiency, sib sib zog nqus pas dej ua ke, siab deposition efficiency, zoo tsos, yooj yim ua hauj lwm, haum rau high-ceev mem tes MIG (GMAW) vuam.

Fast tau cog lus rau R & D thiab kev tsim khoom ntawmhydraulic lub tog raj kheejthiab hydraulic systems, pab cov neeg siv khoom thiab muab cov neeg ua haujlwm nrog lub neej zoo dua.Txog niaj hnub no, peb tau pab ntau txhiab tus neeg siv khoom thoob plaws ntiaj teb-muab kev txawj ntse hauv hydraulic lub tog raj kheej thiab cov qauv tsim nrog kev sib tw zoo.

Post lub sij hawm: Sep-16-2022